What are the advantages of robot glue filling assembly line

source:www.strawberryking.cn | Release time:2025年07月02日1、 High precision operation ensures product consistency

1. Correct control of glue filling amount and trajectory

Using servo motors to drive the robotic arm, coupled with high-precision metering pumps (such as screw pumps and plunger pumps), the injection amount error can be controlled within ± 0.1mg, meeting the micro injection requirements of precision components such as microelectronics and automotive sensors (such as chip packaging adhesive layer thickness ≤ 0.05mm).

Robots can perform complex trajectory gluing in three-dimensional space according to preset programs (such as circular, spiral, linear reciprocating, etc.), avoiding manual shaking or trajectory deviation, especially suitable for encapsulating and gluing irregular workpieces (such as connectors, motor coils).

2. Assembly positioning accuracy reaches micrometer level

Equipped with a visual recognition system (such as a CCD camera) and a force sensor, it can achieve millimeter level positioning of the workpiece during assembly (such as a docking error of ≤ 0.02mm between the PCB board and the housing), and adjust the assembly force through force feedback to prevent component pressure damage (such as the meshing assembly of precision gear sets).

2、 Efficient production capacity and continuous operation capability

1. Short cycle time and significant increase in production capacity

The multi station parallel operation mode (such as synchronous operation of the glue filling station and assembly station) can compress the single product cycle to 10-30 seconds (manual operation takes 2-5 minutes). Calculated on an 8-hour working system, the daily production capacity of a single production line can reach 1000-5000 pieces, suitable for large-scale production (such as consumer electronics parts, automotive parts).

2.24-hour uninterrupted production

The robot system has no fatigue loss and, when combined with automatic feeding mechanisms (such as vibration discs, truss manipulators) and waste recycling devices, can achieve 24/7 continuous operation, especially suitable for scenarios with large order fluctuations or tight delivery times (such as new energy battery pack glue assembly).

3、 Strong material adaptability and compatibility with multiple categories of processes

1. Multiple adhesives and assembly process support

The glue filling process can be adapted to different viscosity adhesives such as epoxy resin, silicone, polyurethane, etc. (viscosity range 100-100000cP), and the flowability of high viscosity adhesives can be improved through temperature control modules (such as preheating glue barrels and heating gun heads); The assembly process can complete various processes such as screw locking, buckle connection, and pressing.

2. Quick switching of multi specification products

By adjusting the glue filling program and fixtures (such as modular fixtures) through software, it is possible to complete the production of different product types within 30 minutes (such as switching between glue filling for mobile phone cases and assembly for router cases), which increases the efficiency of manual wire changing by more than 80%.

4、 Intelligent control and quality traceability

1. Full process data monitoring

The production line integrates MES system to collect real-time process parameters such as glue filling amount, pressure, temperature, assembly torque, etc. It automatically alarms in case of abnormalities (such as insufficient glue amount or low pressure) and generates production reports (such as yield statistics and equipment OEE) for quality traceability and process optimization.

2. Visual inspection and automatic sorting

After gluing, the flatness and bubble rate of the adhesive layer are inspected through 3D vision (such as the requirement for bubble ratio to be less than 0.5% for automotive sensor gluing). After assembly, the clearance between the parts is checked (such as the clearance between the motor rotor and stator ≤ 0.1mm), and non-conforming products are automatically removed, with a yield rate of over 99.5%.

5、 Cost optimization

1. Reduce manual exposure to harmful substances

The glue filling process often involves volatile organic compounds (such as solvent based adhesives), and robot operations can keep workers away from the glue mist environment. With the help of exhaust systems, occupational health risks can be reduced, in compliance with ISO 45001 safety standards.

2. Significant long-term cost advantage

Although the initial equipment investment is higher than that of manual production lines (about 500000 to 2 million yuan/piece), cost recovery can be achieved within 3-5 years through capacity improvement, labor cost savings (reducing 60% -80% of operating workers), and material loss reduction (reducing rubber waste by 30%), especially suitable for labor-intensive enterprises (such as electronic assembly plants).

6、 Flexible production and customized expansion

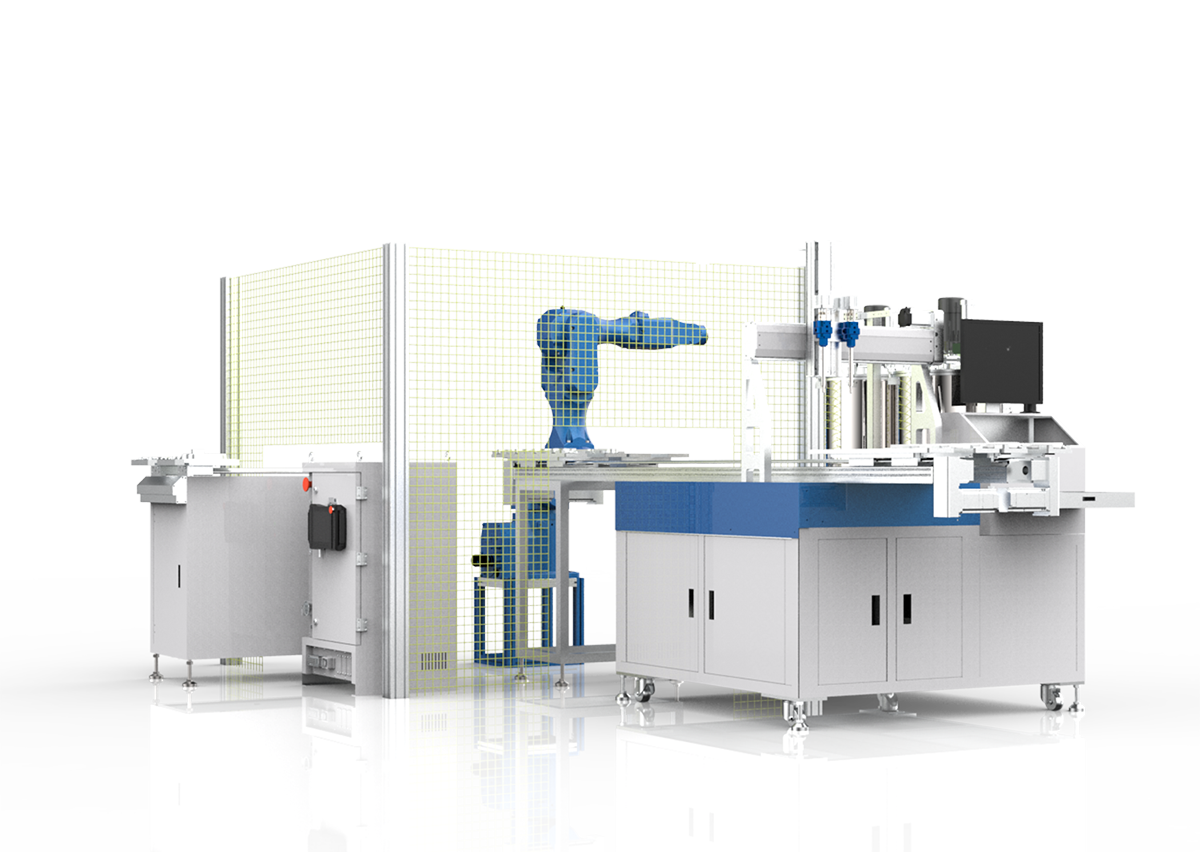

1. Modular design supports production line upgrades

The robot glue filling assembly line can be divided into modules such as glue filling unit, assembly unit, and detection unit according to their functions. Enterprises can gradually expand according to order requirements (such as deploying glue filling+detection modules first and adding assembly modules later) to avoid excessive one-time investment.

2. Small batch and multi variety production adaptation

For personalized products (such as customized parts for medical devices), process parameters can be quickly adjusted through programming to achieve "production as soon as possible" and solve the pain point of "small batch uneconomical" in traditional production lines. For example, the drone battery glue assembly line can simultaneously handle more than 10 battery types.

7、 Typical application scenarios

In the field of electronics and electrical appliances: waterproof glue filling for PCB boards, sealing assembly for LED lighting fixtures, insulation glue filling for relays;

Automotive manufacturing: sensor gluing, motor coil packaging, and assembly of in car cameras;

New energy industry: lithium battery pack encapsulation, photovoltaic inverter sealing, energy storage battery module assembly;

Medical equipment: syringe piston assembly, sensor probe gluing, minimally invasive surgical instrument packaging.

prev:

In which industries is the sealing vacuum defoami…

next:

Why is automatic glue coating line used in packag…

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone